Ken-React® CAPS® KPR® 12/LV and Ken-React® KPR® Rezyk-1240 Pellets · Ken-React® CAPOW® KPR® 12/LH and Ken-React® KPR® Rezyk-1280 Powders

KEN-REACT® CAPS® KPR® 12/LV PELLETS AND KEN-REACT® CAPOW® KPR® 12/HV POWDER (AMERICAS/ASIA)

KEN-REACT® KPR® REZYK-1240 PELLETS AND KEN-REACT® KPR® REZYK-1280 POWDER (EU REACH)

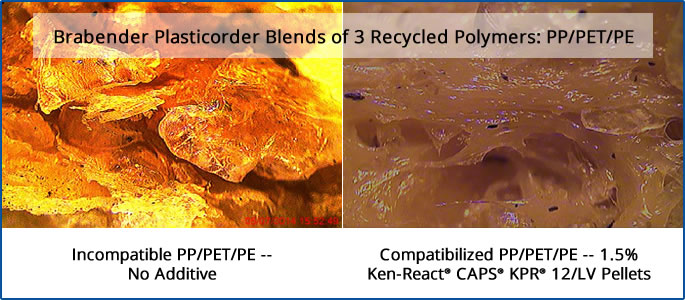

Introduced at FAKUMA 2014 in Friedrichshafen, Germany and built on the monoalkoxy titanate platform, Kenrich claims 1.5% of a new single site titanium/mixed metal catalyst masterbatch named Ken-React®KPR® Rezyk-1240 Pellets regenerates PCR (Post-Consumer Recycle) plastic mixtures to virgin like properties – and acts as a compatibilizer between dissimilar polymers. For example, 50% of recycled PP can be added to HDPE to make injection molded parts that do not delaminate. “Normally – although PP and HDPE are both considered olefins – HDPE cannot accept more than 5% PP without creating incompatibility issues. The additive pellet can be used just like a color concentrate, but must be melt compounded at ~10% lower temperatures than normal to create reactive compounding shear because the catalyst reduces melt viscosity. The lower temperature is necessary to impart the optimal Work Energy (quantified as the Area under the plot of Torque vs.Time) at the interface of the dissimilar macromolecules to optimize the 1.5-nanometer catalyst’s complete reaction”, explains Monte, inventor and company President.

A Ken-React® KPR® Rezyk-1280 Powder with twice the activity designed for compounders is also introduced.

Samples may be obtained by contacting FARRL GmbH (Austria, Germany, Hungary, Poland, Romania, Slovak Republic, Slovenia), F.IN.CO s.r.l. (Italy) or Kenrich Petrochemicals, Inc.

KEN-REACT® CAPS® KPR® 12/LV PELLETS AND KEN-REACT® CAPOW® KPR® 12/HV POWDER (AMERICAS/ASIA) is built on the neoalkoxy titanate platform:

Click for Ken-React® products and Kenrich’s full product list

Place Order Request Sample